Perforated Kraft Paper

Introduction:

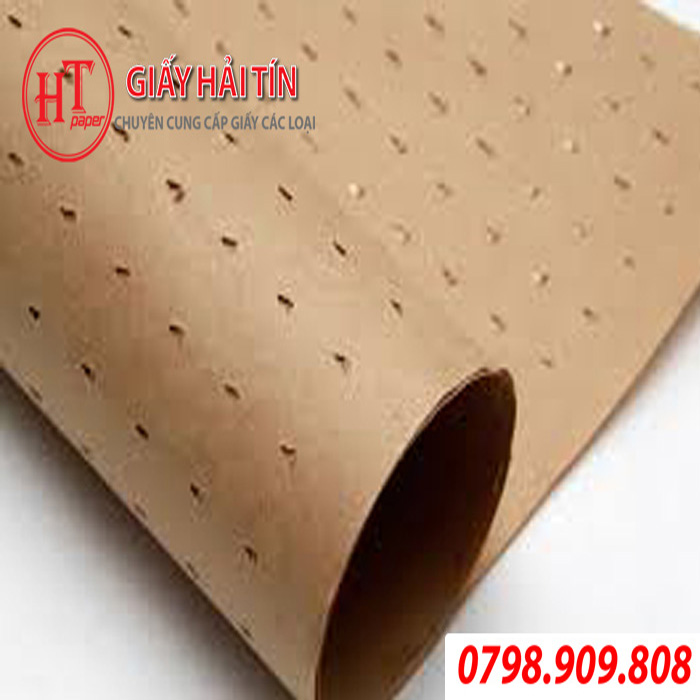

Perforated fabric lining paper is placed under each fabric layer and vacuumed to ensure that the layers do not stick to each other during machine operation. Depending on the requirements of each unit, the density of the holes in the perforated paper varies. For thin fabrics like lingerie or sportswear, dense perforation is applied, while for thicker fabrics like denim, canvas, or faux leather, wider hole spacing is used.

Specifications:

Product Name: Perforated Paper - Perforated Pattern Paper

Type of Perforated Paper: White Recycled Paper, Yellow Recycled Paper

Basis Weight of Perforated Paper: 75 g/m²

Dimensions of Perforated Paper: 130, 160, 172, 185, 198 cm

Weight of Perforated Paper: 35-40 kg/roll

Product Description:

Perforated paper is manufactured from a variety of materials, including mixed pulp paper, recycled paper, and virgin pulp paper.

The characteristic features of perforated paper used for fabric lining or spreading include a smooth, straight, and durable texture. The paper can be stretched without tearing and ensures good air ventilation through the perforations.

By applying perforated paper appropriately in the garment industry, production processes are optimized, labor productivity is increased, work efficiency is enhanced, and costs are significantly reduced.

Packaging Method:

Perforated paper is packaged with outer wrapping paper or PE film depending on customer shipping requirements, protecting it from water and dust.

More Information:

For detailed information on high-quality perforated paper in Ho Chi Minh City at the best prices, please contact our company for product consultation and attractive purchasing policies for perforated paper in the garment industry.